FAQ

How does a hose pump works?

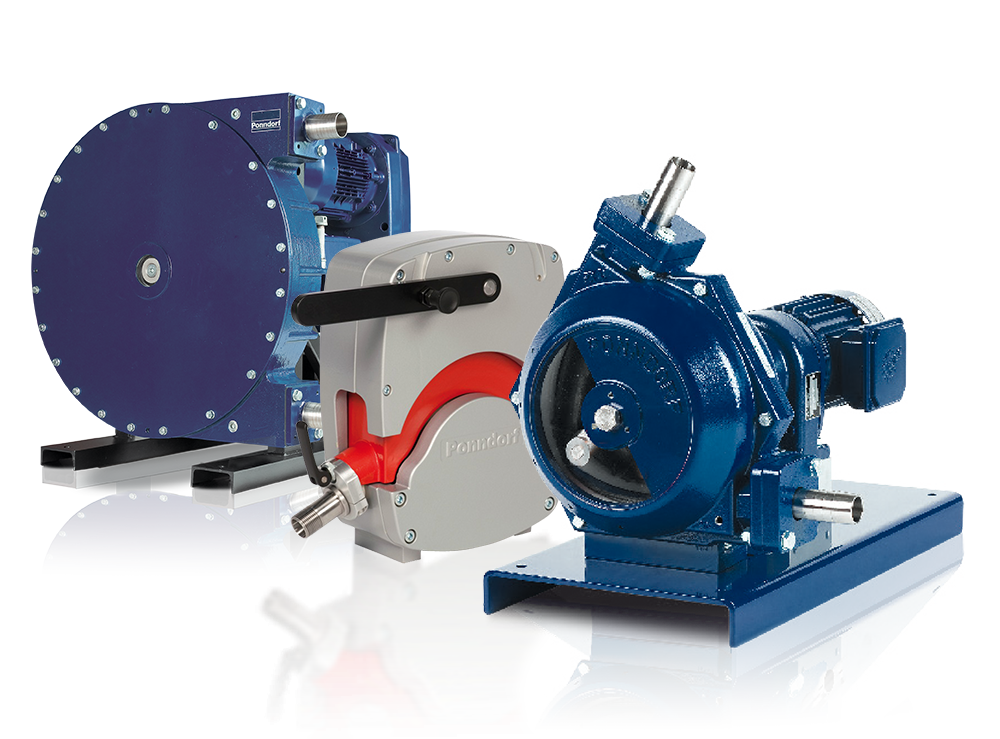

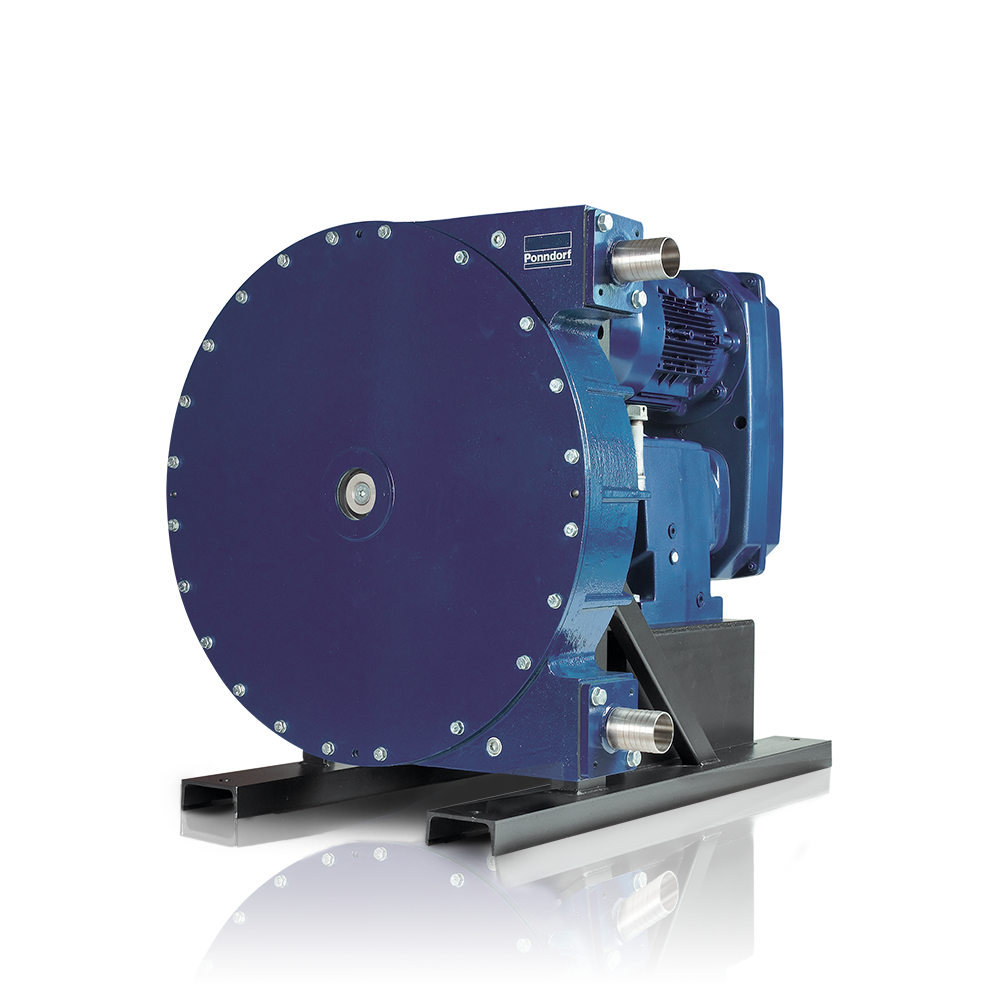

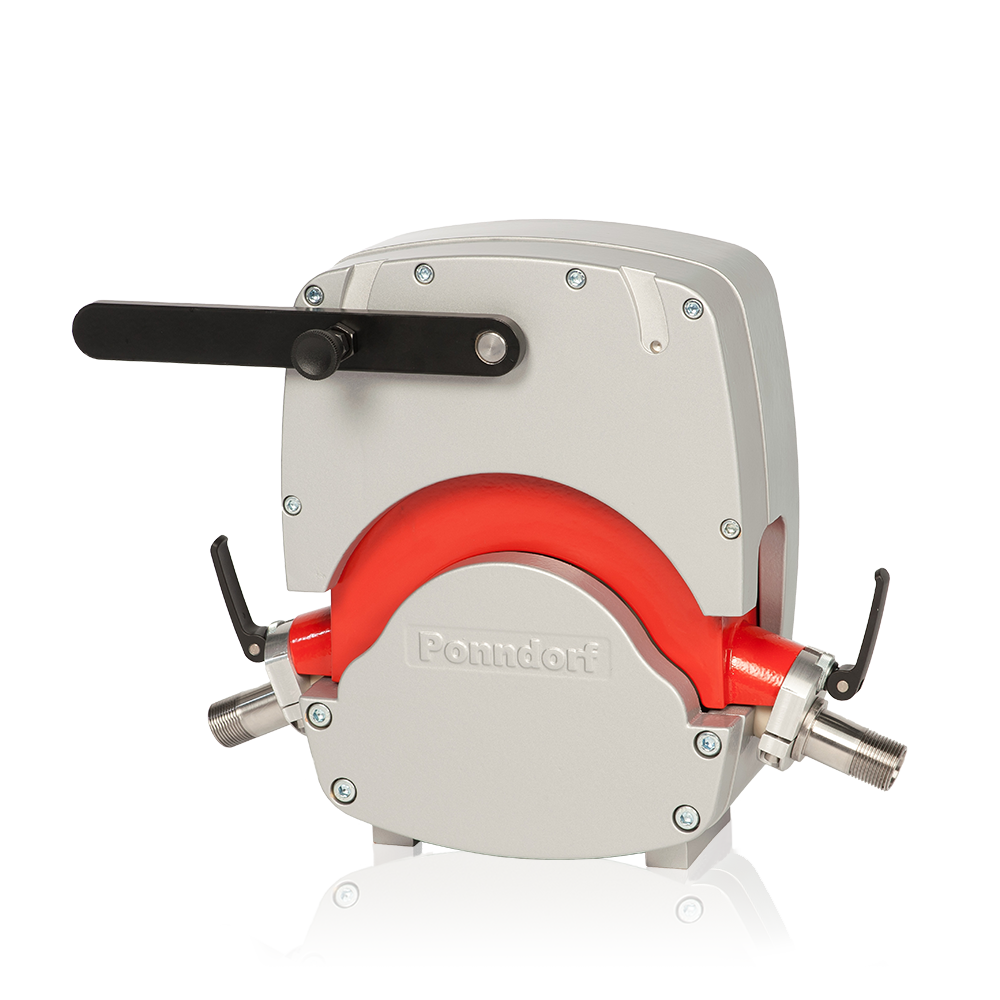

Ponndorf Hose Pumps are self-priming displacement pumps which are safe to run dry.

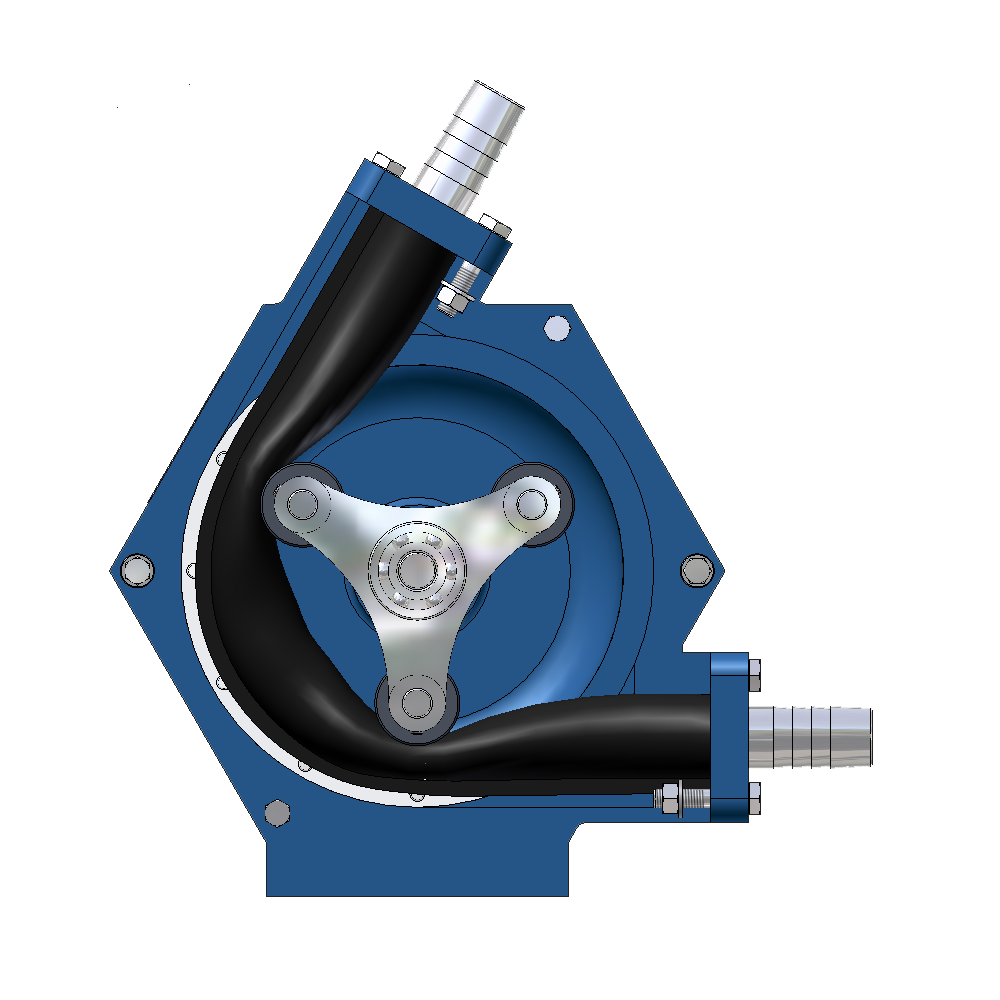

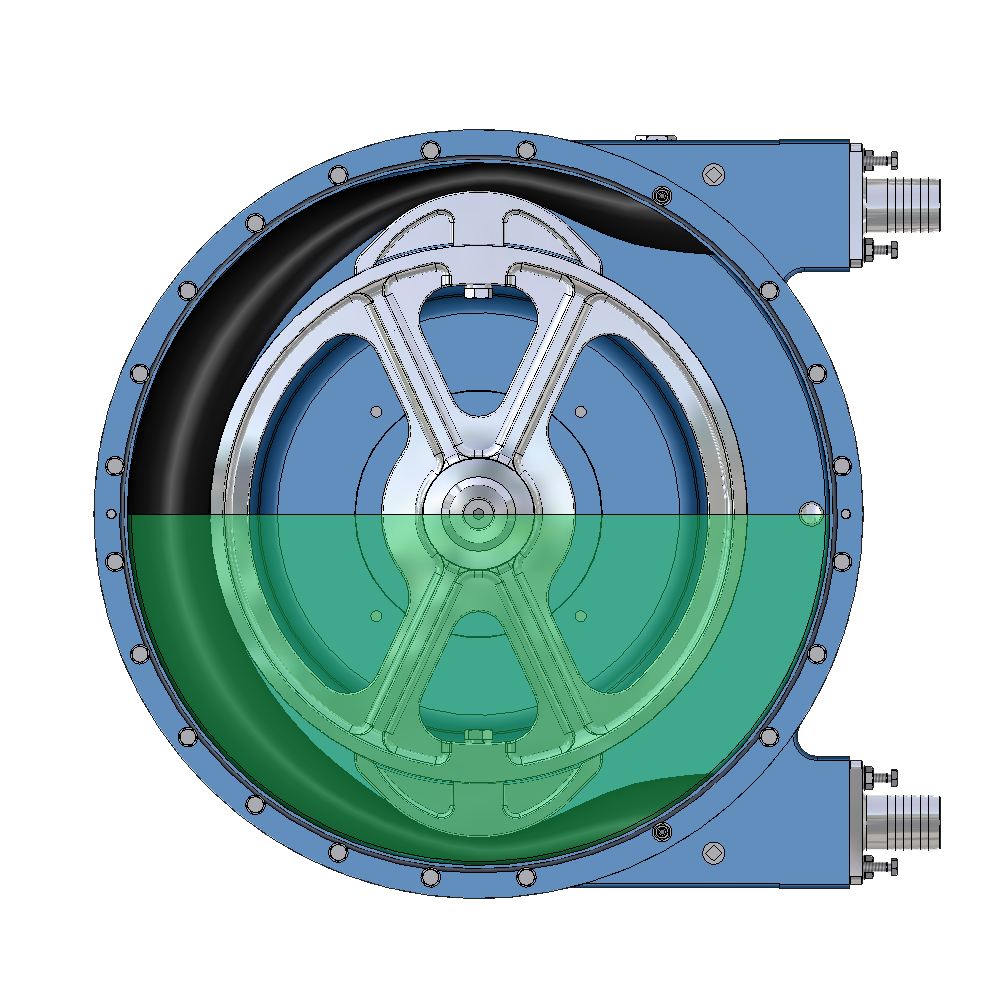

A medium resistant, flexible hose is pressed together - at dry running system by teflon rollers and at the lubricated system by gliding shoes. By rotation of the rotor the medium in the hose is pushed foward. The resetting of the hose to its round shape creates an underpressure which induces the suctin of the following medium. As hose pumps re self-priming no filling of the pipeline is necessary at suction process. Because of the pumping principle all liquids which "pass through the hose" can be pumped irrespective of whether they are abrasiv, aggressive or containing solids.

That´s why Ponndorf Hose Pumps are a universal problem solver - even for challenging pump jobs!

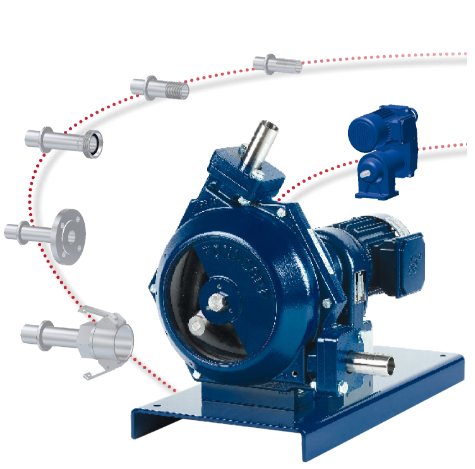

Why two systems – what is the difference between dry running and lubricated systems?

Ponndorf is one of a few pump manufacturers that specializes in both - dry running and lubricated systems. The parameters of the application are decisive for the suitable pump principle.

If these parameters permit the use of a dry runner - which applies to 70% of the pumps required - this system offers many advantages for the user.

The lubricated system is ideal for applications that place higher demands on the required pressure and flow rate.

Both pump systems are also available as double-head pumps - for applications that require low pulsation.

Are hose pumps according to FDA?

Highest quality standard must be guaranteed, especially in the food industry. The medium only comes in contact with he hose and can be pumped particularly gently through the optimal selection of the components.

- fruits or similar will not be destroyed

- no dead spots

- hoses according to FDA and EU/2011 available

Does my pump resist applications with aggressive fluids?

At aggressive media, e.g. in chemical and pharmaceutical industry, hich resistance and conveyance without contacting metallic materials is guaranteed in order to eliminate harzardous reaction with the medium.

Therefore hose pumps offer:

- high chemical resistance

- suitable for acids / leaches

- no damage of medium components such as crystals

- no contact with metals

Does high flow rates and solids raise problems?

Day-to-day our our self-priming pumps fulfill have to perfom high flow rates while being insensitive to solids withoud plugging. They do not need any seals, flaps or additional valves.

They are

- robust against solids

- self-priming out of sewer

- no plugging

- high flow rates are possible

Is gentle pumping possible?

For example, gentle processing is essential when pumping pumping paints and varnishes. In addition, easy cleaning and short shutdown time when changing the hose are the decisive factors to ensure trouble-free service.

Hose Pumps offer:

- gentle pumping withour shear forces

- no foaming of the medium

- easy cleaning